Direct-to-Movie (DTF) transfer sheets are a unique advantage in custom printing, offering a flexible and great technique for applying plans to different materials. Nonetheless, accomplishing perfect outcomes expects scrupulousness and a first rate process. Here is the ultimate checklist to guarantee faultless direct to film transfers sheet application like clockwork.

Pick Quality Transfer Sheets

Begin with excellent DTF transfer sheets to guarantee energetic and durable outcomes. Decide on trustworthy brands that offer predictable performance and fantastic variety devotion. Quality sheets are essential for accomplishing the best outcomes and staying away from normal issues like unfortunate grip or variety blurring.

Set up Your Plan

Before printing, guarantee your plan is accurately formatted. Utilize high-goal pictures and make sure that the plan fits the components of the transfer sheet. Focus on subtleties like tones, goal, and drain regions. If necessary, change your plan in visual communication programming to meet the determinations expected for a perfect transfer.

Keep up with Printer Settings

Guarantee your printer settings are upgraded for DTF printing. Utilize the suggested settings for print quality, paper type, and ink profiles. Routinely align your printer to keep up with variety exactness and stay away from issues with print quality. Allude to the maker’s rules for the best outcomes.

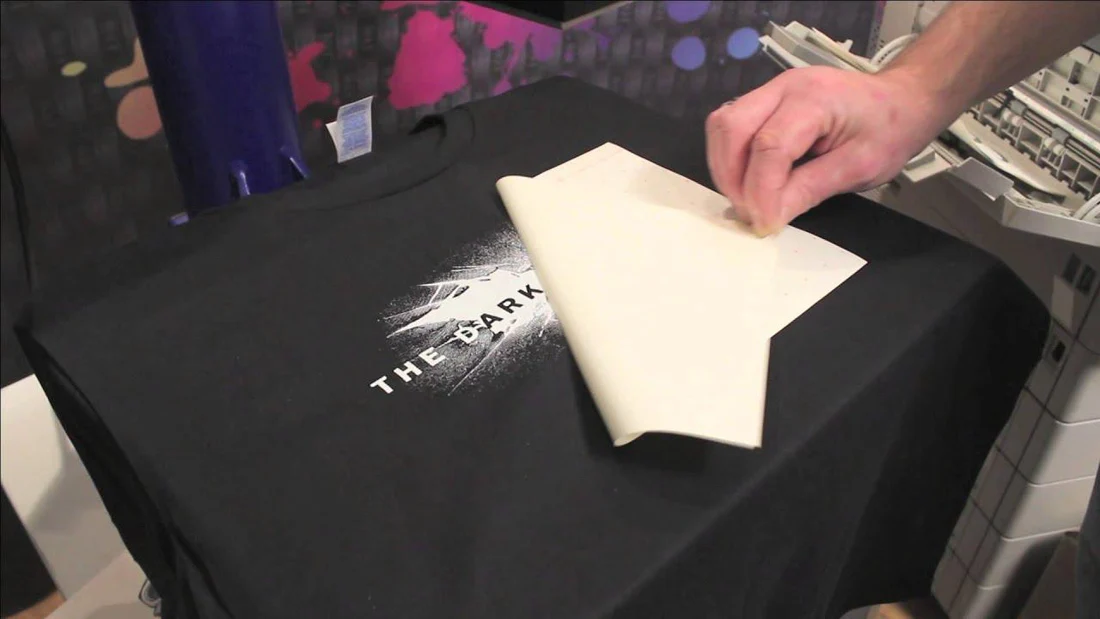

Set up the Transfer Sheet

Before applying the plan, ensure the transfer sheet is spotless and liberated from residue or flotsam and jetsam. Handle the sheets with clean hands or gloves to try not to transfer oils or soil that could influence bond. In the event that your transfer sheets accompany a defensive film, eliminate it cautiously before use.

Utilize the Right Cement Powder

Applying cement powder is a basic move toward the DTF interaction. Guarantee you utilize the proper kind and measure of glue powder for your particular transfer sheet and plan. Equitably cover the printed plan with the powder, keeping away from clusters that can influence the transfer quality. Adhere to the maker’s directions for application and relieving.

Preheat the Press

Preheat your intensity press to the suggested temperature for the transfer sheet you are utilizing. Exact temperature control is fundamental for legitimate bond and energetic variety transfer. Continuously utilize an intensity press with a reliable and customizable temperature setting to guarantee uniform outcomes.

Apply the Transfer

Cautiously position the direct to film transfers sheet on the objective material. Utilize an intensity press with even strain to apply the transfer. Follow the suggested time and temperature settings given by the transfer sheet producer. Press the transfer equitably to keep away from lopsided application or missed regions.

Accomplishing a perfect DTF transfer sheet application includes cautious consideration regarding each step of the cycle. By following this ultimate checklist, you can guarantee dynamic, durable plans that fulfill high guidelines of value. From picking the right materials to sticking to suggested rehearses, these means are fundamental for fruitful DTF transfers and fulfilled clients.